Our Cutting-Edge Compounding, Raising the BAR

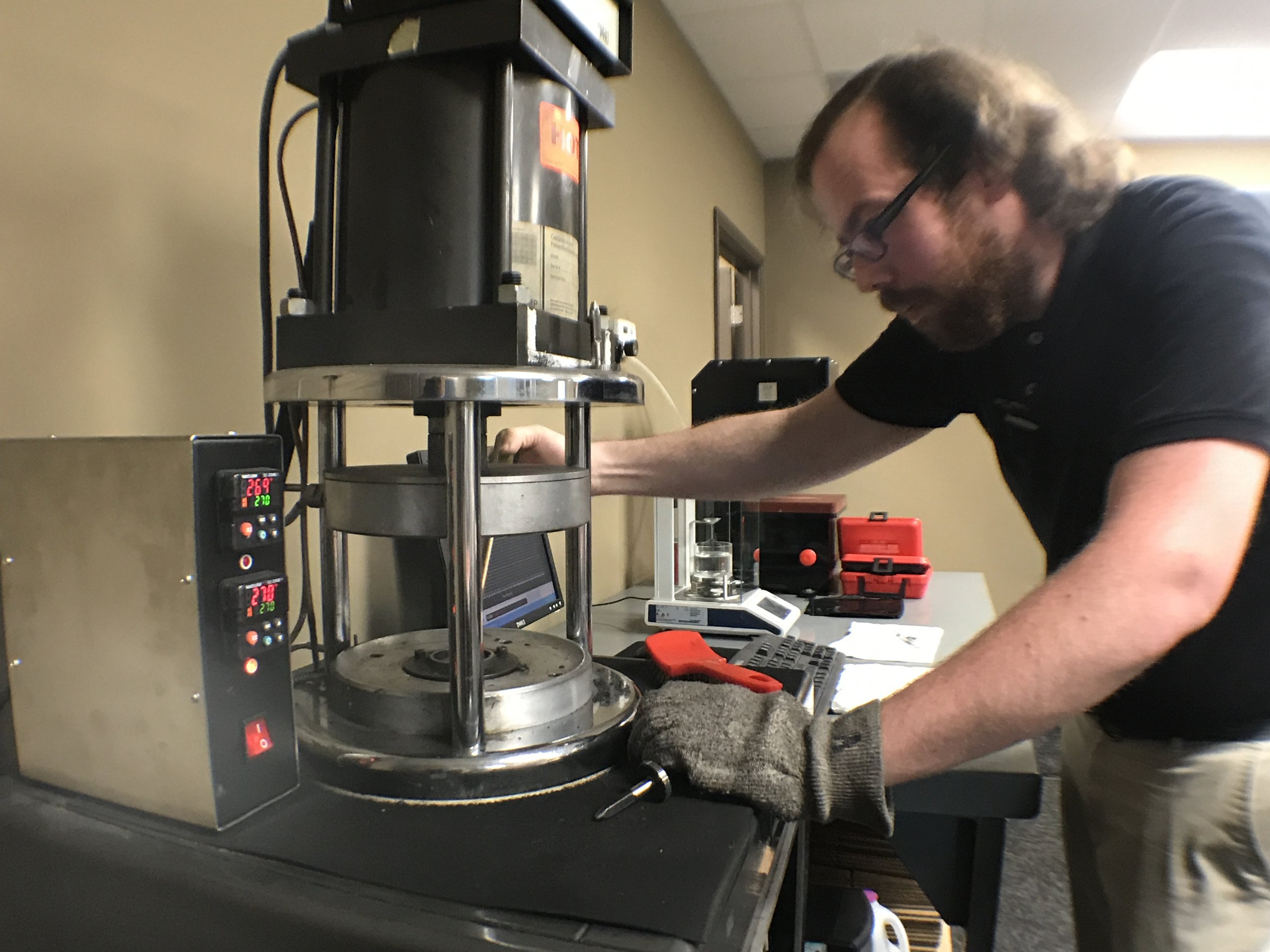

State-of-the-Art Manufacturing Equipment

At BARCO, we don't just manufacture rubber products—we engineer consistency in every batch. Our 182,000 sq ft facility houses an impressive array of advanced equipment designed to deliver precision, consistency, and superior quality with every production run.

High-Performance Mixing Systems

Our mixing capabilities represent the backbone of our production excellence:

KSBI 3700: 414-liter Tangential mixer with typical batch sizes of 650-1000lbs, depending on the specific gravity, going to a 100" drop mill underneath the mixer that feeds into an 84" take-out mill.

GK 320: 351-liter Intermesh mixer with a typical batch size of 450-550lbs. There are two inline strainers underneath this mixer with two 84" mills.

110L Tilt Mixer — For vibrant color compounds and specialized non-black formulations, our tilt mixer delivers exceptional dispersion quality and color consistency that sets your products apart.

Superior Calendering Technology

Transform raw compounds into perfectly engineered sheets with our advanced calendering systems:

4-Roll Inverted "L" Calender — This specialized equipment produces flawless rubber sheets with precise thickness control and superior surface quality, critical for demanding applications.

Extended Calendering Capabilities — We've invested in versatile calendering solutions that allow us to accommodate a wide spectrum of product specifications, from ultra-thin to heavy-gauge materials.

Mixing Capabilities

We specialize in the mixing of black and colored compounds. Our expertise includes the following polymers:

- Natural Rubber

- SBR

- PBD

- NBR

- XNBR

- EPDM

- Neoprene (CR)

- Polyisoprene (IR)

Environmental & Safety Infrastructure

We take our environmental responsibility seriously with systems designed for safety and sustainability:

Advanced Dust Collection System — Our facility maintains exceptional air quality and cleanliness through state-of-the-art dust collection, providing a safer working environment while ensuring product purity.

Comprehensive Oil Management

Two massive indoor storage tanks (10,000 and 20,000 gallons) handle our large-volume production needs

Multiple smaller, specialized tanks house specialty oils for custom formulations

All storage systems are maintained indoors with rigorous containment protocols, demonstrating our commitment to environmental protection

At BARCO, our investment in technology isn't just about equipment—it's about providing you with rubber solutions that exceed expectations.

Our Industry Leaders for over 30 years

-

Mike Cash

With over four decades of transformative leadership in the rubber industry, Mike Cash brings unparalleled expertise and visionary direction to every aspect of our operations. As President and CEO, Mike combines deep technical knowledge with exceptional business acumen to guide BARCO's continued growth and innovation.

Industry Veteran, Visionary Leader

Mike's journey through the rubber industry spans more than 40 years, during which he has mastered every facet of rubber manufacturing and business operations. His hands-on approach and comprehensive understanding of both traditional techniques and cutting-edge technologies have positioned BARCO as an industry leader.

Strategic Direction

As the driving force behind BARCO's executive team, Mike:

Oversees daily operations with meticulous attention to quality, efficiency, and customer satisfaction

Architects long-term strategies that anticipate market shifts and technological advancements

Fosters a culture of innovation that empowers our team to develop groundbreaking rubber solutions

Maintains personal connections with key clients, ensuring their evolving needs remain our priority

Industry Recognition

Mike's contributions to the rubber industry extend beyond BARCO, where he has served on multiple industry boards and advisory committees, helping shape standards and best practices that elevate the entire sector.

"The rubber industry isn't just about manufacturing products—it's about engineering solutions that move industries forward. At BARCO, we're committed to being the partner that helps our clients overcome their toughest challenges through innovation, quality, and exceptional service."

— Mike Cash, President & CEO

Under Mike's leadership, BARCO continues to push boundaries, embrace new technologies, and deliver rubber solutions that exceed expectations—establishing our reputation as not just a manufacturer, but a true innovation partner.

-

James O'Quinn

Vice President & General Manager

James O'Quinn brings a powerful combination of technical expertise and operational leadership to BARCO's rubber mixing division. With over a decade of specialized experience in the rubber industry, James drives operational excellence while consistently pushing the boundaries of what's possible in rubber formulation and processing.

Rubber Industry Expert

Since joining BARCO, James has transformed our mixing operations through strategic improvements and an unwavering commitment to quality:

Advanced process optimization that has increased production efficiency by 30% while enhancing product consistency

Implementation of rigorous quality control protocols that exceed industry standards

Development of innovative mixing techniques for specialty compounds with unique performance requirements

Cross-functional leadership that bridges technical capabilities with customer-focused solutions

Operational Leadership

As Vice President and General Manager, James oversees all aspects of our rubber mixing operations:

Daily production management across multiple mixing lines

Strategic resource allocation to maximize efficiency and minimize downtime

Team development focusing on technical skills advancement and safety excellence

Quality assurance oversight ensuring every batch meets BARCO's exacting standards

Continuous improvement initiatives that keep BARCO at the forefront of manufacturing technology

Technical Innovation Champion

James's background in rubber chemistry and processing technology makes him a valuable resource for clients with challenging technical requirements. His ability to translate complex formulation challenges into manufacturable solutions has made him a trusted advisor to customers across diverse industries.

"The foundation of exceptional rubber products begins in the mixing room. By combining precise formulation with advanced processing techniques, we create compounds that deliver exactly what our customers need—whether that's extreme durability, specific performance characteristics, or consistent quality at scale."

— James O'Quinn, VP & General Manager

Professional Development

James holds advanced certifications in rubber technology and manufacturing management, and regularly participates in industry conferences to stay at the cutting edge of rubber mixing innovations. His commitment to continuous learning ensures BARCO remains ahead of industry trends and technological developments.

Under James's leadership, BARCO's mixing operations have become synonymous with precision, reliability, and innovation—delivering compounds that meet the most demanding specifications while maintaining the efficiency needed to compete in today's market.